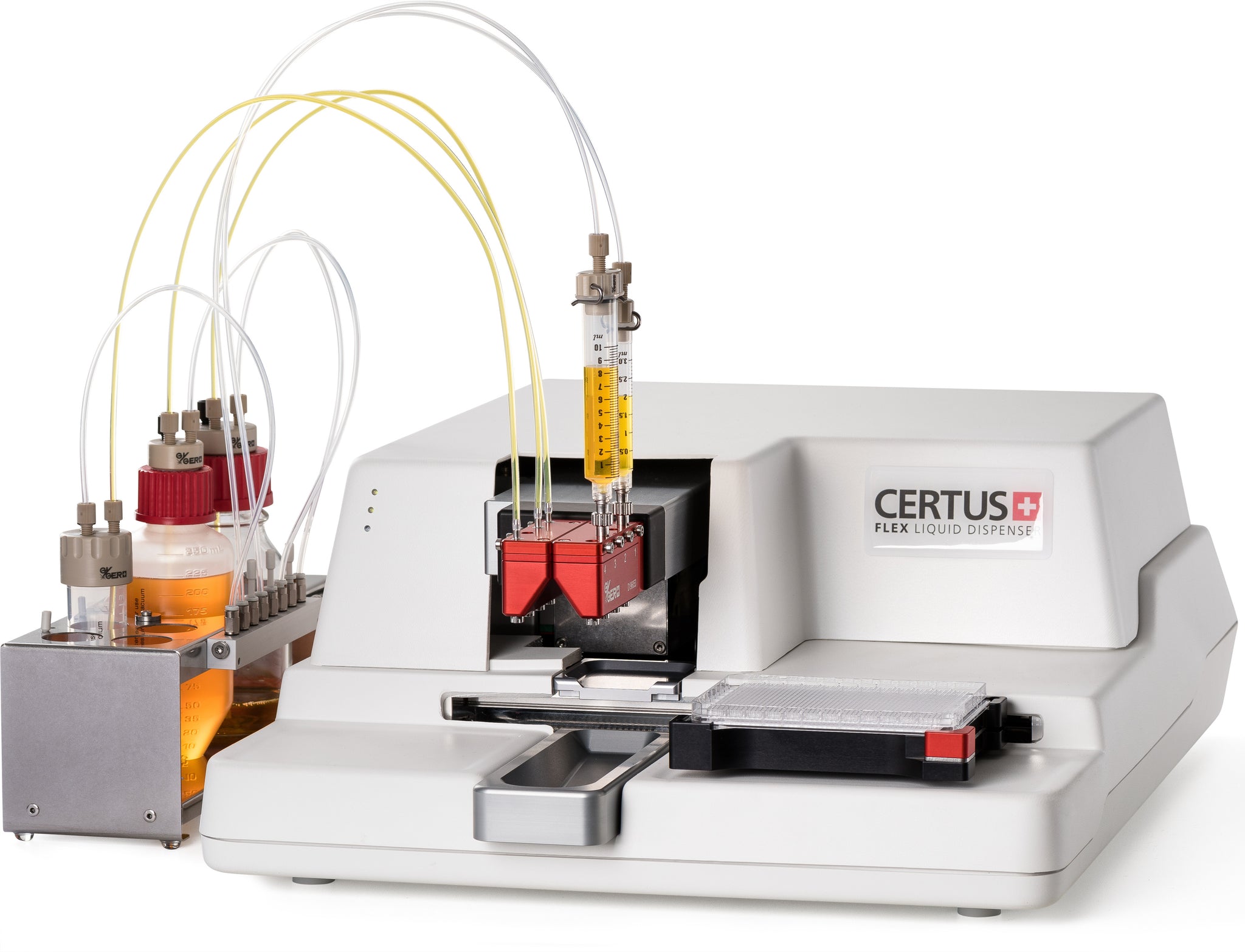

Unparalleled Accuracy, Precision and Flexibility

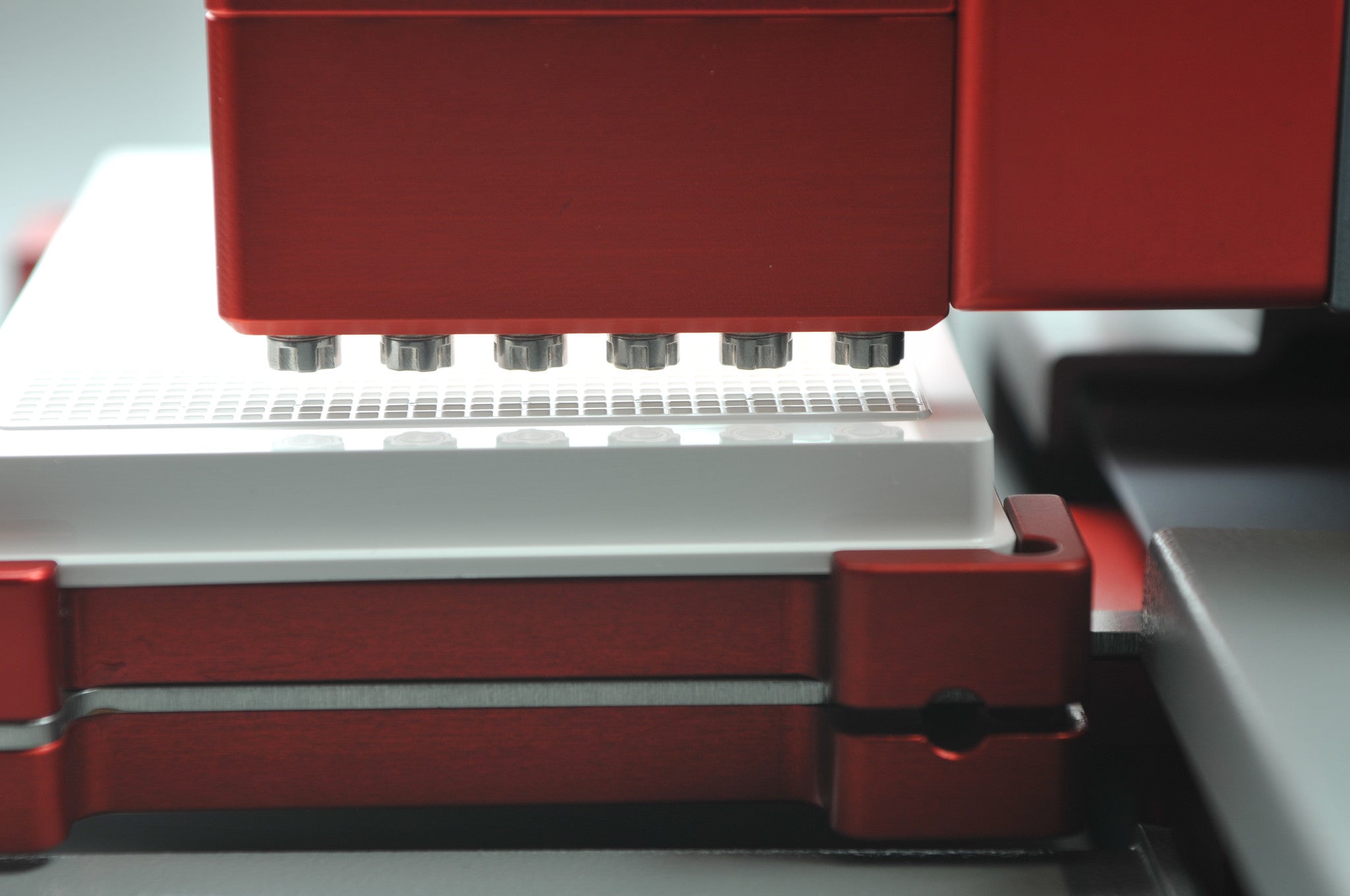

The Certus FLEX has been developed for contactless dispensing of a broad range of liquid substances and large molecules, using Gyger's renowned microvalve technology and air pressure control, giving you maximum precision and flexibility..

Flexible fluid uptake options to meet your exact needs

Fluids can be supplied to the dispenser from bottles and tubes for bulk dispensing, or from syringes to achieve the lowest dead volumes. This allows you to more effectively dispense smaller volumes and high value substances from luer-lock syringes (from 3 - 60mL).